Material Transfer

Have you ever thought of a vacuum to vortex?

Material transfer facilitates the movement of substances, like powders and granules, from one area to another in an industrial or processing setting. This technique relies on vacuum suction force to move bulky materials through a network of pipes. Vacuum-based material transfer is commonly used in food processing, textile production, and pharmaceutical manufacturing, where accurate and regulated material handling is crucial for streamlining production processes and upholding product standards.

From here to there, but how exactly?

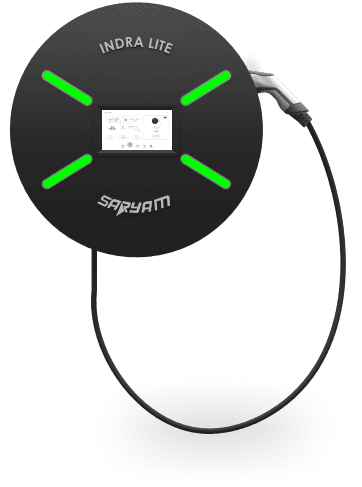

Vacuum turbine

A vacuum turbine is the main component for transferring materials by rapidly rotating to create vacuum pressure. This suction force propels substances through the pipe system.

Silo

A silo is a spacious container with a capacity ranging from 100kg to 750kg, designed to hold substances. It has a self-cleaning pneumatic filter and a motorised butterfly valve. The motorised butterfly valve enables controlled discharge of the stored material from the silo as required.

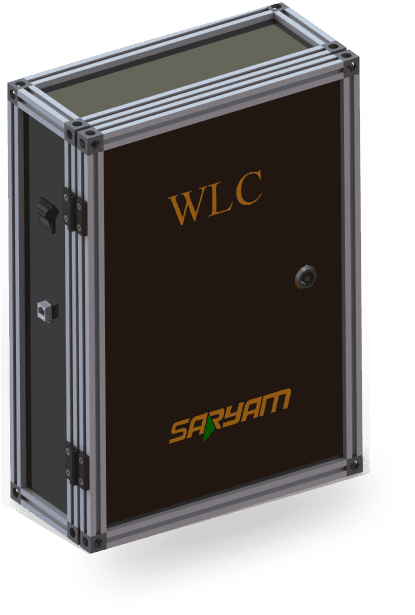

Control System

The material transfer system combines a control system with a 5.5-inch display to offer live updates on the substance transformation process. It also utilises MODBUS technology, a communication protocol that enables smooth data exchange and interaction among system elements.

It's highly beneficial in...

Food processing

Flour

Sugar

Cereals & Grains

Starch

Rice

Spices

Textile & Chemical

Dyes

Raw materials

Chemical compounds

Mines & Construction

Ores

Minerals

Coal

Sand

Gravel

Cement

Pharmaceutical

Excipients

Intermediates

APIs

Polymers

Plastics

Resins

Pellets